Description

| Cook Chill Return on Investment: Return on investment (ROI) for a small cook chill system may take 2 to 5 years, shorter or longer, depending upon how agressively the owner or operator runs the system. This may include changing from a 7 day production week to 5 day week. (please contact Cleveland Range LLC Cook Chill for assistance and more information), cooking back to back batches, changes in purchasing and inventory paramenters and other factors. Analyzing the ROI should include not just the cook chill food production but also the resulting savings in food, labor, and other sections of the operation such as retherming products, tray service, replacement of expensive convenience foods, changes in staff both in the centralized operation and the receiving facilities. |

| Kettle Production: Typically a food service facility has a menu where 40 to 60% of the menu items can be cooked in steam kettles. Using a mixing kettle improves cooking time and reduces labor while maintaining the high quality of the kettle items such as soups, sauces, stews, casseroles, pie fillings, salad dressings and many more items. |

| Factory Support: Since Cook Chill Advanced Food Production Systems are unique, a Factory Support package is recommended to provide drawings, installation, technical and operations support from the beginning and throughout the project. Cleveland Range, LLC is known to provide the most thorough Factory Support to cook chill customers. Please see section on Cleveland Range LLC Factory Support for Cook Chill. |

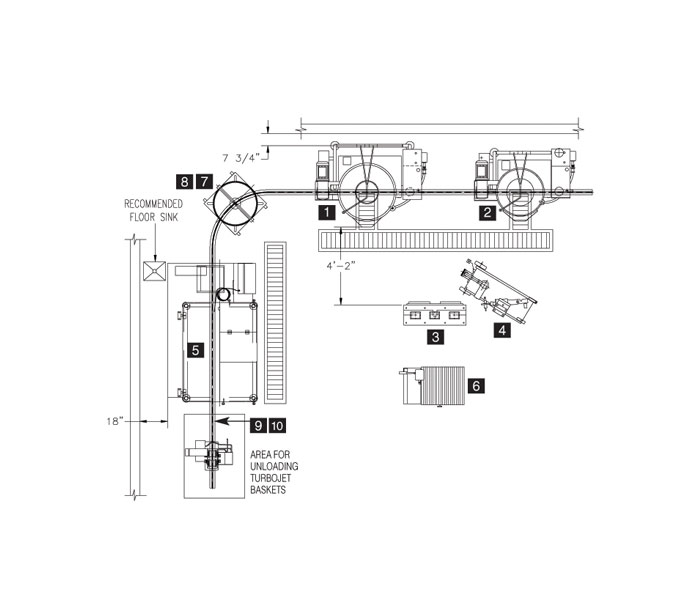

| Basic Principles of Cook Chill: Cleveland Range Cook Chill is defined as an Advance Food Production System where food is cooked in Kettles, quickly pumped into bags and rapidly chilled in an ice water bath to 40 degrees or less in an average of 45 minutes to meet the USDA Guidelines. Additionally, meats that are vacuum packaged and cooked through the Cook Tank Process meet the USDA Guidelines of chilling in less than 6 hours. Bagged menu items can be easily transported and heated in the bags or re-portioned into serving containers for sale or tray rethermalization. |

| Cook Tank Production: Cook Tank Production: While somewhat unknown to many food service operators, cook tanks produce large volumes of food from 300 to 2000 lbs per batch while providing huge savings. An example of a cook tank food is deli turkey. Cleveland Cook Chill Operators can produce their own deli turkey and other roasts. Some advantages are:1. Reduced shrinkage of the finished turkey from 25% shrinkage to less than 10% shrinkage when compared to an oven cooked turkey.2. Improved slicing and reduced crumbling or tearing of the meat because it is more moist than an oven product and can be sliced cold while retaining its shape.3. Fast ROI, (return on investment) resulting from reduced losses noted above and ease of handling.4. Consistently high quality. |

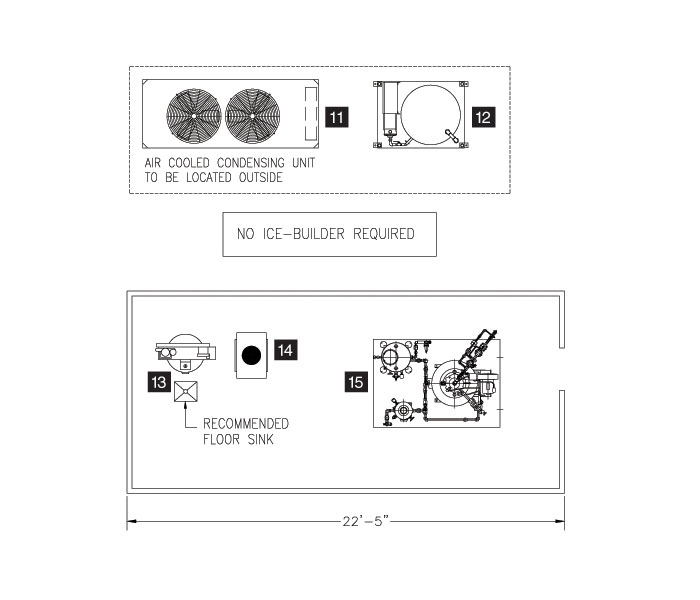

| TurboJet, Cook Tank: The unique feature of this example is the Turbo Jet Chiller/Cook Tank. The heat-exchange system for cooling water eliminates the need for an ice builder, supporting mechanical pieces for the ice builder and regular treatment of ice builder water. It has rapidly grown in popularity for cook chill operations that use kettles 100 gallons or smaller. |